Aluminium Pressings

Our capabilities in Aluminium include Pressings, Cladding, Cills, Rollings, Flashings, and Soffits

At our factory, we boast a diverse range of capabilities to cater to your specific needs in aluminium pressings, cladding, cills, rollings, flashings, and soffits. Our advanced equipment, including shears and a brake press, enables us to handle a variety of projects with precision and efficiency.

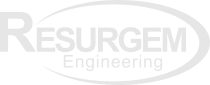

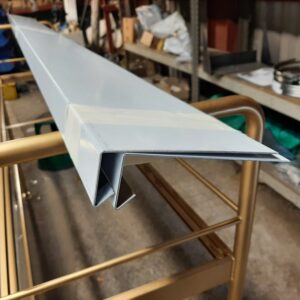

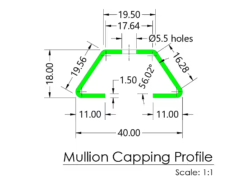

Aluminium Pressings:

– Our shears and brake press allow us to fabricate aluminium pressings up to an impressive length of 4000mm.

– For larger pressings exceeding this length, our skilled team can weld sections together seamlessly or provide joint sections for on-site assembly.

Comprehensive Project Support:

– From initial concept sketches to the delivery of the finished product, we offer end-to-end support for your requirements.

– Whether you desire a raw aluminium finish, powder coating, or a sprayed finish, we have the expertise to fulfill your requirements.

Advanced Press Brake and Forming Tools:

– Utilizing our 4-meter press brake, along with cutting-edge punching and forming tools, we can fabricate complex parts with precision.

– Our extensive knowledge in sheet metal welding ensures that we can deliver high-quality and structurally sound components.

Give us a call on 01179372846 or visit our contact page to enquire about aluminium pressings.

Contact our talented engineers today to discuss your project or send us your drawings using the handy contact form.

We pride ourselves on possessing cutting-edge capabilities in shearing and bending aluminium, offering a seamless and versatile solution for your fabrication needs. Our commitment to precision and innovation sets us apart in the industry.

Shearing Excellence: Equipped with advanced shearing machinery, we have the capability to efficiently cut aluminium sheets up to an impressive length of 4000mm.

This precision shearing process ensures clean, accurate cuts, allowing us to work with large aluminium pieces while maintaining the highest standards of quality.

Bending Mastery: Our skilled engineers bring a wealth of expertise to the table, enabling us to bend aluminium with precision and finesse.

The bending process is a crucial aspect of metal fabrication, and our team is adept at manipulating aluminium into an array of shapes, sizes, and angles, providing endless possibilities for your project.

Endless Variety of Shapes, Sizes, and Angles: With our skilled engineers at the helm, we take pride in our ability to press a nearly endless variety of shapes, accommodating diverse design requirements.

Whether your project demands intricate curves, precise angles, or unique geometries, our team has the expertise to bring your vision to life.

Tailored Solutions for Your Project: We understand that each project is unique, and our capabilities are designed to provide tailored solutions that align with your specific requirements.

From small-scale components to large architectural elements, our shearing and bending capabilities ensure the successful fabrication of aluminium parts that meet your exact specifications.

Discover our unparalleled expertise in aluminium cills, flashings, and soffits, where form meets function seamlessly. We offer a comprehensive understanding of these architectural elements, combining precision craftsmanship with versatile capabilities.

Custom Shapes and Sizes: Explore limitless design possibilities with our ability to craft aluminium cills in any shape, providing tailored solutions to match your unique vision. From standard designs to highly customized features, we bring your ideas to life.

Seamless Integration of Sections: Experience a uniform and visually cohesive look with cills up to 4000mm in one piece. For longer lengths, our expert welding ensures both structural integrity and aesthetic continuity.

Welding Excellence: Our skilled craftsmen excel in welding aluminium, creating joints that are robust and seamlessly integrated. This expertise allows for extended lengths without compromising strength or visual appeal.

Joint Straps for In-Situ Connection: Opt for flexibility in installation with our supplied joint straps. Perfect for on-site assembly, these components facilitate the connection of sections in situ, adapting to your project’s unique requirements.

Tailored Solutions for Every Project: Whether it’s residential, commercial, or industrial, our capabilities are designed to provide bespoke solutions. Trust us to deliver quality components that align with your project’s distinct needs.

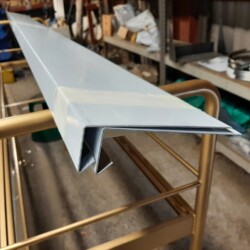

Transforming existing buildings is a breeze with our top-notch aluminium cladding solutions. We’ve got the expertise to make your structures look brand new, and here’s why our aluminium cladding stands out:

Large Surface Coverage: Our aluminium cladding is a game-changer when it comes to covering existing buildings. With the ability to handle up to 4000mm lengths, we can seamlessly cover large surface areas with minimal joints. This means a smoother, more aesthetically pleasing finish for your project.

Minimal Joints for Maximum Impact: Our capability to cover expansive surfaces with fewer joints ensures a sleek and uniform appearance. The result? A polished, modern look that enhances the overall aesthetic of your building.

Customized Powder Coating: We understand that colour matters. That’s why we offer the flexibility to powder coat our aluminium cladding in any color you desire. Whether you’re looking for a bold statement or a subtle blend with the surroundings, we’ve got the perfect color options to bring your vision to life.

In collaboration with our cutting-edge press, we deliver aluminium rolling services that extend to crafting cylinders or cones effortlessly. Here’s how our capabilities stand out in the realm of aluminium rolling:

Precision Collaboration with Our Press: Our rolling operations seamlessly integrate with our state-of-the-art press, creating a synergy that allows us to transform aluminium sheets into precisely shaped cylinders or cones. This precision ensures that your desired forms are achieved with accuracy and finesse.

Crafting Cylinders and Cones with Expertise: Whether it’s cylinders or cones, we possess the technical prowess to roll aluminium into these specialized shapes. Our skilled team navigates the intricacies of the rolling process, resulting in smooth, uniform, and structurally sound components.

Tailored Flat Patterns for Laser Cutting: In addition to rolling, we offer an advanced capability to develop flat patterns for any shape or size, ready for laser cutting. This ensures a meticulous approach to preparing the material before the rolling process, allowing for precision and efficiency in achieving the desired shapes.